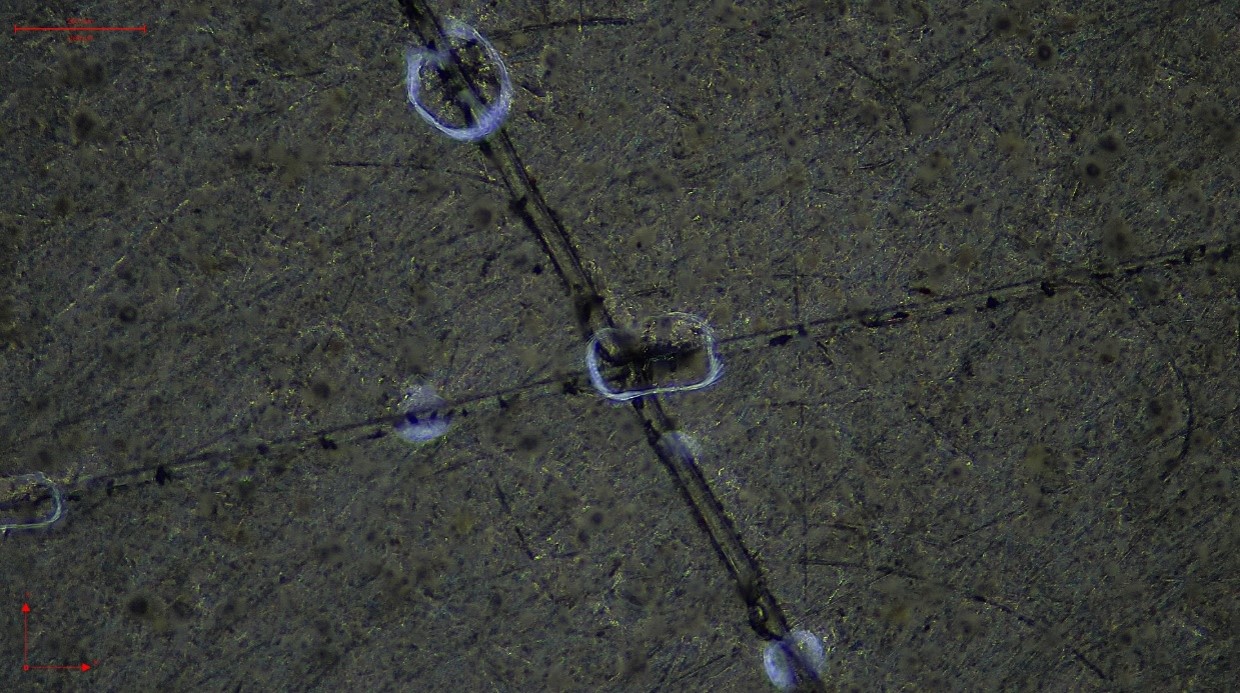

使用光学显微镜观察埋植改性GO微胶囊涂层的划痕区域的修复状况。制备步骤:20wt%GO改性微胶囊和固化剂微胶囊加入6gE51和4g602A,搅拌10min,再加入3.85g718A。用四面制备器刮涂于钢板上,湿膜厚度200μm,室温固化24h。在涂层表面制造"X"划痕,光学显微镜观察相隔7天的划痕愈合。

The repair status of the scratch area of the embedded modified GO microcapsule coating was observed using an optical microscope. Preparation steps: 20wt% GO modified microcapsules and curing agent microcapsules were added with 6gE51 and 4g602A, stirred for 10min, and then 3.85g718A was added. The steel plate was scraped with a four-sided preparer, the wet film thickness was 200μm, and it was cured at room temperature for 24h. "X" scratches were made on the surface of the coating, and the scratch healing was observed with an optical microscope 7 days apart.