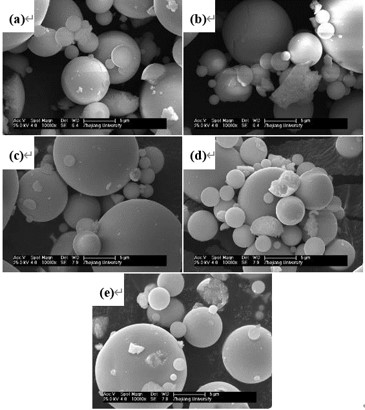

图为经过不同温度热处理后氧化锆微球的SEM照片。由图可知,热处理温度升至900 ℃,球状结构依然完整,无明显畸变。推测在热处理过程中,凝胶中有机物的挥发及分解速率较低,因此有机物的挥发及分解对氧化锆球状结构的影响较小;同时,由于在热处理过程中产生的晶粒尺寸较小,产生的应变较小,不足以使凝胶球体发生显著的形变。因此,在整个热处理过程之后,氧化锆凝胶球体仍能保持较好的球状结构。此外,根据图所示900 ℃热处理后所得粉体的断面形貌可知,其内部结构仍为实心结构,未见核壳结构的形成。其较小的晶粒尺寸所导致的较低结晶度,可能导致在整个快速升温热处理过程中,外部无法形成有效的刚性壳层。因此,直到升温至900 ℃,其内部仍然保持了实心结构,而无中空核壳结构形成。因此,氧化锆微球可作为涂料辅助填料使用。

The picture shows the SEM photos of zirconia microspheres after heat treatment at different temperatures. As can be seen from the figure, when the heat treatment temperature rises to 900 ℃, the spherical structure is still intact without obvious distortion. It is speculated that the volatilization and decomposition rate of organic matter in the gel is low during heat treatment, so the effect of volatilization and decomposition of organic matter on the spherical structure of zirconia is small. At the same time, due to the small grain size generated in the heat treatment process, the strain generated is small, which is not enough to cause significant deformation of the gel sphere. Therefore, after the whole heat treatment process, zirconia gel spheres can still maintain a good spherical structure. In addition, according to the sectional morphology of the powder obtained after heat treatment at 900 ℃, it can be seen that its internal structure is still solid, and no core-shell structure is formed. The low crystallinity caused by its small grain size may result in the inability to form an effective rigid shell on the outside during the entire rapid heating heat treatment process. Therefore, until the temperature rises to 900 ° C, its interior still maintains a solid structure, and no hollow core-shell structure is formed. Therefore, zirconia microspheres can be used as auxiliary fillers for coatings.