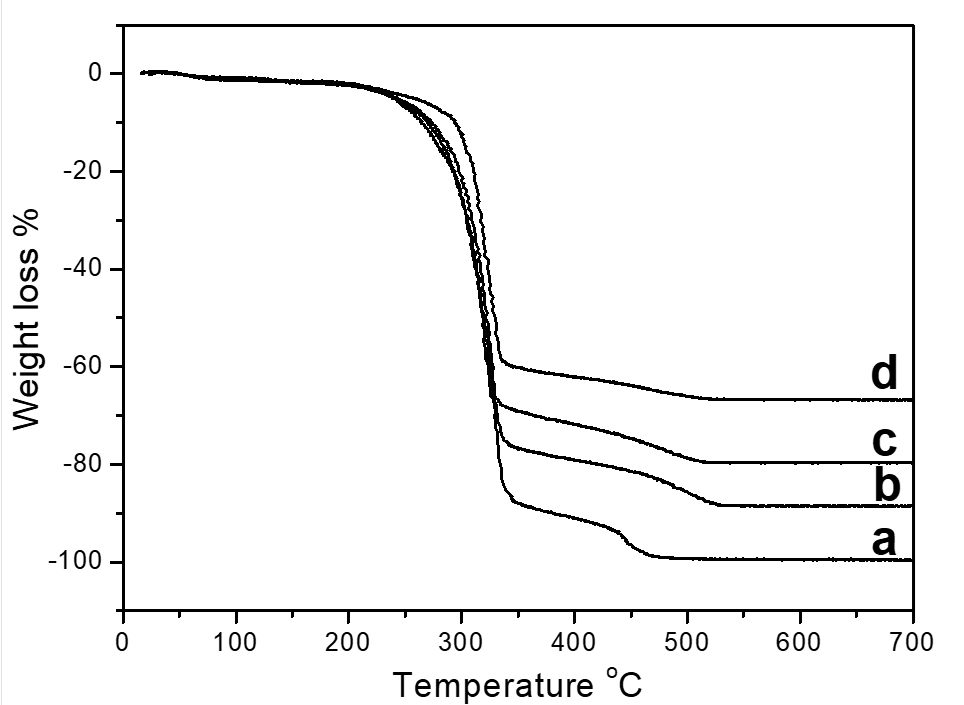

图表明,利用不饱和乙酸乙酯水溶液为第一步乳化水相所得到的乙基纤维素粉体,相比有乙酸乙酯饱和水溶液所得粉体,有更大的孔径。由于油相液滴中的乙酸乙酯溶于水相的过程是由扩散控制的,当油相液滴尺寸较大时,液滴内乙酸乙酯在水相中的溶解过程就被减慢,因为较大的液滴尺寸使得油水间界面面积降低并且可能增加了乙酸乙酯的扩散路径。而这就为油相液滴内部相分离相的粗化及聚并提供了充足的时间,从而在固化时,得到了具有较大孔径的内部结构。

The figure shows that the ethylcellulose powder obtained by using unsaturated ethyl acetate aqueous solution as the first emulsified water phase has a larger pore size than that obtained by saturated aqueous solution with ethyl acetate. Since the dissolution of ethyl acetate in oil droplets in water phase is controlled by diffusion, the dissolution process of ethyl acetate in water phase is slowed down when the size of oil droplets is larger, because the larger droplet size reduces the interface area between oil and water and may increase the diffusion path of ethyl acetate. This provides sufficient time for the coarsening and polymerization of the internal phase separation phase of the oil phase drop, so that the internal structure with a larger pore size is obtained during curing.